Thermal Imaging System for Failure Analysis and Troubleshooting

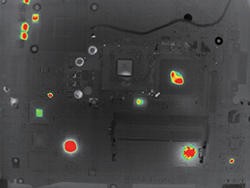

TRUSEE Failure Analysis and Troubleshooting Thermal Imaging System provides a powerful non-contact method of PCB failure analysis taking advantage of infrared temperature measurement and unique Lock-in algorithm. Inhomogeneous temperature distribution, local power loss, leakage currents and soldering issues can be measured with this system, which provides two orders of sensitivity increase compared with traditional thermography methods.

Product description

TRUSEE Failure Analysis and Troubleshooting Thermal Imaging System provides a powerful non-contact method of PCB failure analysis taking advantage of infrared temperature measurement and unique Lock-in algorithm. Inhomogeneous temperature distribution, local power loss, leakage currents and soldering issues can be measured with this system, which provides two orders of sensitivity increase compared with traditional thermography methods.

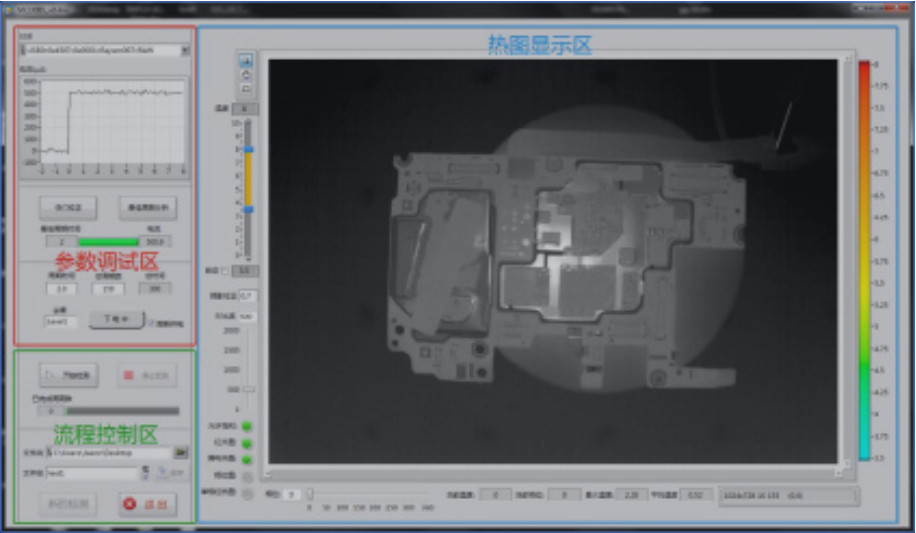

◆ Software Interface

– Clear and user-friendly UI;

– Real-time thermography display with integrated color modes;

– 0-90° phase diagram display, check heat dispersion procedure frame by frame;

– Highlighted abnormal heat spot, 3D heat map display;

– Higher location accuracy with thermography-RGB image fusion technology;

– Customizable functions;

◆ 6 Advantages

Ultra high sensitivity

0.001K temperature difference、microampere leakage detectable

NETD<=50mK

Advanced Lock-in technology and 3D

filtering algorithm

High Accuracy of Positioning

1024*768 FPA detector

thoroughly customized motorized lens

Positioning accuracy up to 20μm, can

locate 01005 package components

Thermography-RGB image fusion

technology available

Wide Range of Application

Max Input voltage:15V

Max working current:3A

Max detection area:

300mm×250mm (M type)

700mm×550mm (L type)

Rich Detection Functions

Fast location of heat sources with

amplitude display

Phase diagram helps to distinguish heat

dispersion timing

Accurate location with thermography-RGB

image fusion technology

Device current waveform detectable

Traditional thermography mode available

Reliable and stable

Detector with high stability

Passed through rigorous reliability

tests

EMI tests passed

With overcurrent protection

User friendly

Small size desk-top equipment

Only 1 USB cable needed for

communication

Clear and simple interface

Results can be updated and saved for

subsequent analysis

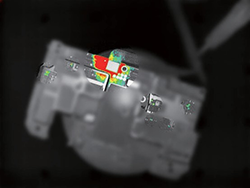

– Case 1:Mobile phone circuit board repair

Electronic components on mobile phone circuit boards are small and densely arranged. Circuit repair requires high image resolution and ultrahigh sensitivity to detect low to micro-ampere leakage currents, which could hardly achieve by traditional methods.

Our customer realized the failure location and analysis of most of this kind of mobile phone circuit boards by TRUSEE M-type equipment, and obtained high economic benefits.

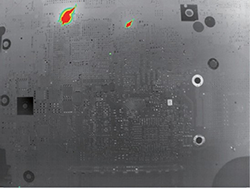

– Case 2:Verification and Failure Analysis of Telecommunications Equipment Circuit Boards

Telecommunication equipment circuit boards are usually of large size, expensive and complex,making product verification and failure location very difficult. This type of circuit boards needs to be compared and verified between normal ones.

Our customer uses TRUSEE L-type device with dual power supply and large field of view and realized highly efficient and low-cost inspection and maintenance.

– Case 3:R&D Center Applications

Some circuits need to be debugged repeatedly during R&D process. It is often difficult to figure out reasons of abnormal functions caused by current leakage. For some complex circuit boards, location of failure often cost several weeks or even longer time, which brings great impact of project process and increased risk. Our customer introduced our equipment and most of the abnormalities can be located within a few minutes, which greatly improves the efficiency and guarantees the project progress.