AlN submount

Trusee can provides AlN submount with high thermal conductivity, to provide solutions for heat dissipation of high power semiconductor laser diode, electrode connection, solder preset and assembly positioning.

Product description

Trusee can provide high thermal conductivity submount for COS packaged semiconductor laser. With good quality and stability, our products provide solutions for the heat dissipation of high power semiconductor laser chips, the connection of the electrode, the preset of the solder and the positioning of the assembly.

– Substrate:AlN、BeO、SiC etc

– Dimension:customizable

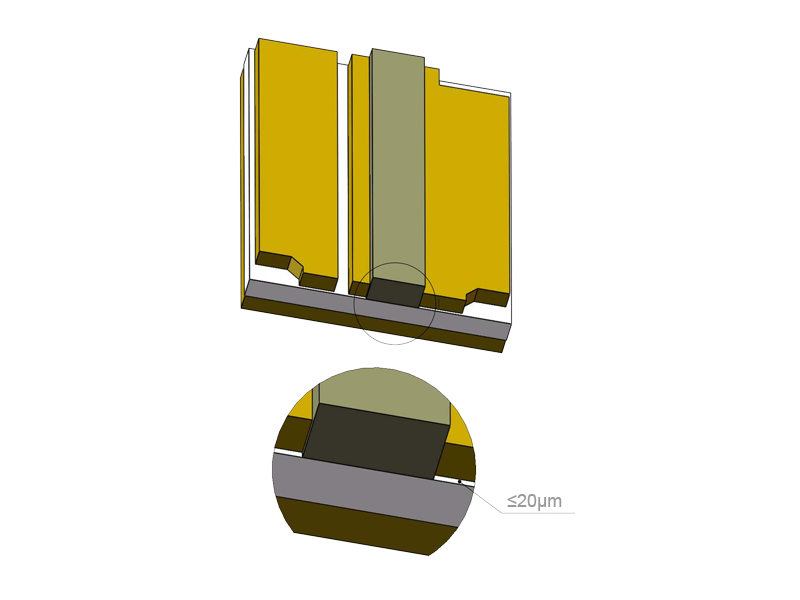

– Metallization:Cu/Ni/Au, Cu thickness 75μm ± 15 μm,Au suit for wire bonding,other layers can be customized

– AuSn layer:Au(75±5wt%)Sn,proportion and thickness can be customized

– Graphic accuracy:±30 μm

| Substrate | Unit | AlN | BeO | ||

| Thermal conductivity | W/(m·K) | >200 | >230 | >250 | |

| Roughness | μm | <0.3 | <0.3 | <0.3 | |

| CTE | 40 ~ 400 ℃ | ×10-6/K | 4.6 | 4.6 | 6.8 |

| 40 ~ 800 ℃ | ×10-6/K | 5.2 | 5.2 | 8.4 | |

| Thickness | mm | 0.25 ~ 1.5 ± 10% | |||

——————————————————————————————————————————————————————————————————

AlN Submounts: Applications and Specifications

Aluminum Nitride (AlN) submounts have emerged as critical components in modern electronic and optoelectronic devices, primarily due to their superior thermal conductivity, electrical insulation properties, and mechanical strength. These materials serve as a foundation for mounting various semiconductor devices, particularly in high-power and high-frequency applications where thermal management is crucial. This article delves into the specifications, applications, and advantages of AlN submounts.

Material Properties:

Thermal Conductivity: AlN exhibits exceptional thermal conductivity, typically in the range of 170-200 W/m·K. This property enables efficient heat dissipation from electronic components, enhancing performance and reliability.

Electrical Insulation: With a high dielectric strength (over 10 kV/mm), AlN submounts effectively insulate electrical components from one another, preventing short circuits and ensuring operational safety.

Mechanical Strength: AlN possesses excellent mechanical stability, with a high tensile strength and resilience to thermal shock, making it suitable for various environmental conditions.

Coefficient of Thermal Expansion (CTE): The CTE of AlN is approximately 4.7 ppm/°C, which is compatible with many semiconductor materials, minimizing stress during thermal cycling.

Applications of AlN Submounts

High-Power Electronics:

AlN submounts are extensively used in high-power devices, such as power amplifiers and RF devices. Their excellent thermal conductivity ensures efficient heat dissipation, preventing overheating and extending the lifespan of components.

Optoelectronics:

In the realm of optoelectronics, AlN submounts are vital for mounting laser diodes, light-emitting diodes (LEDs), and photonic devices. They provide a stable platform that supports efficient thermal management, crucial for maintaining optimal performance in lighting and communication applications.

Semiconductor Packaging:

AlN is commonly employed in semiconductor packaging solutions, especially for devices that generate significant heat. By serving as a substrate for die attach, AlN submounts help ensure reliable thermal and electrical connections between the semiconductor die and the package.

Sensors:

AlN submounts find applications in sensor technology, particularly in high-temperature sensors and gas sensors. Their thermal stability and insulation properties enhance the performance and reliability of these devices in challenging environments.

Automotive Applications:

As automotive technology advances, AlN submounts are increasingly utilized in electric vehicles (EVs) and hybrid systems. They support power electronics and battery management systems, contributing to the overall efficiency and safety of the vehicle.

Aerospace and Defense:

In aerospace applications, where reliability and performance are paramount, AlN submounts are employed in critical systems, including radar and communication devices. Their ability to withstand extreme temperatures and mechanical stresses makes them ideal for such applications.

Telecommunications:

AlN submounts play a crucial role in telecommunication devices, especially in high-frequency applications like 5G technology. They help ensure stable performance and efficiency in base stations and related infrastructure.

AlN submounts are integral to the performance and reliability of modern electronic and optoelectronic devices. With their exceptional thermal conductivity, electrical insulation properties, and mechanical strength, they are poised to play an increasingly important role across various industries. As technology continues to advance, the development of AlN materials and their applications will likely expand, paving the way for enhanced device performance and innovative solutions.