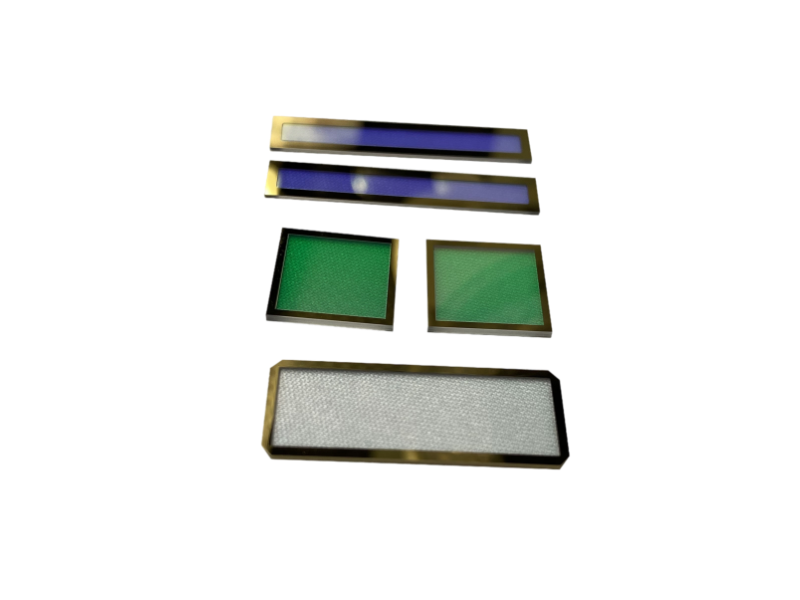

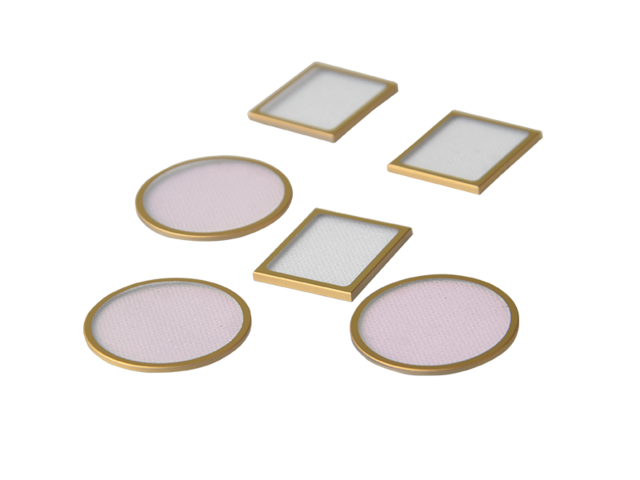

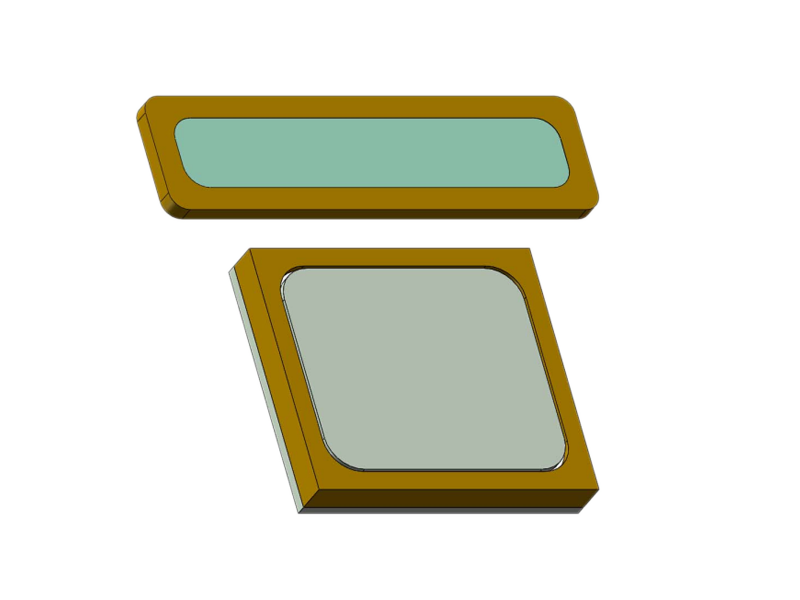

Metallized Sapphire Window

Trusee can provide different size of metallized sapphire window for LiDAR technologies which is used on autopilot.

Product description

Metallized Sapphire Windows: Applications in Hermetic Sealing

Metallized sapphire windows are engineered optical components that combine the durability of sapphire with a metallic coating, providing exceptional performance in various demanding environments. Their unique properties make them essential in applications requiring hermetic sealing, where maintaining a controlled atmosphere is crucial.

Key Properties

Sapphire, a form of aluminum oxide (Al₂O₃), is renowned for its high hardness, thermal stability, and optical transparency across a wide range of wavelengths. When metallized, sapphire windows can provide additional functionalities, such as enhanced electrical conductivity and protective coatings, which are essential for hermetic sealing applications.

Applications

1.Aerospace and Defense: In aerospace systems, where components are often subjected to extreme temperatures and pressures, metallized sapphire windows offer robust protection for sensors and optical systems. They are used in environmental monitoring instruments and targeting systems, ensuring reliable performance in harsh conditions.

2.Telecommunications: These windows are utilized in fiber optic communication systems, where they serve as protective barriers for lasers and photodetectors. Their metallized surface can facilitate electrical connections while maintaining optical clarity, which is vital for efficient data transmission.

3.Medical Devices: In medical applications, such as endoscopes and imaging systems, metallized sapphire windows provide a sterile barrier while allowing clear optical access. They are used in hermetically sealed medical instruments to protect sensitive electronics from contamination and moisture.

4.Industrial Sensors: Metallized sapphire windows are integral to various industrial sensors, including pressure and temperature sensors. Their ability to withstand aggressive environments and provide hermetic seals helps ensure the reliability and longevity of these devices in critical applications.

5.Laser Systems: In laser technologies, metallized sapphire windows are used to protect laser cavities and beam paths. The combination of optical transparency and hermetic sealing ensures that the internal components remain isolated from environmental factors that could affect performance.

6.Robotics and Automation: As robotics increasingly integrates sophisticated sensing technologies, metallized sapphire windows play a critical role in protecting cameras and sensors used for navigation and object detection. The hermetic sealing capability prevents dust and moisture ingress, extending the lifespan of these components.

7.Automotive Applications: In modern vehicles, particularly in advanced driver-assistance systems (ADAS) and autonomous vehicles, metallized sapphire windows are employed in sensors and cameras. They provide robust protection against the elements while allowing for high-performance imaging.

8.Semiconductor Equipment: In the semiconductor manufacturing process, metallized sapphire windows are used in vacuum and inert gas environments. They help maintain the integrity of the process by providing a hermetic seal while enabling optical monitoring and control.

9.Consumer Electronics: Devices like smartphones and tablets can benefit from the use of metallized sapphire windows, particularly in camera modules. These windows protect delicate components while allowing for high-quality image capture, all within a compact design.

Metallized sapphire windows represent a significant advancement in the field of optical materials, particularly for applications requiring hermetic sealing. Their ability to combine the hardness and thermal stability of sapphire with the benefits of metallization makes them invaluable across various industries. As technology continues to evolve, the demand for these versatile components is expected to grow, leading to further innovations in design and application.

– Substrate:sapphire, customizable

– Optical feature:customizable

– Metallization:Ti/Pt/Au,Cr/Ni/Au,etc, qulified for AuSn brazing

– Graphic accuracy:≤ 0.15mm,up to 0.05mm

– Surface quality:better than MIL-PRF-13830B 40/20